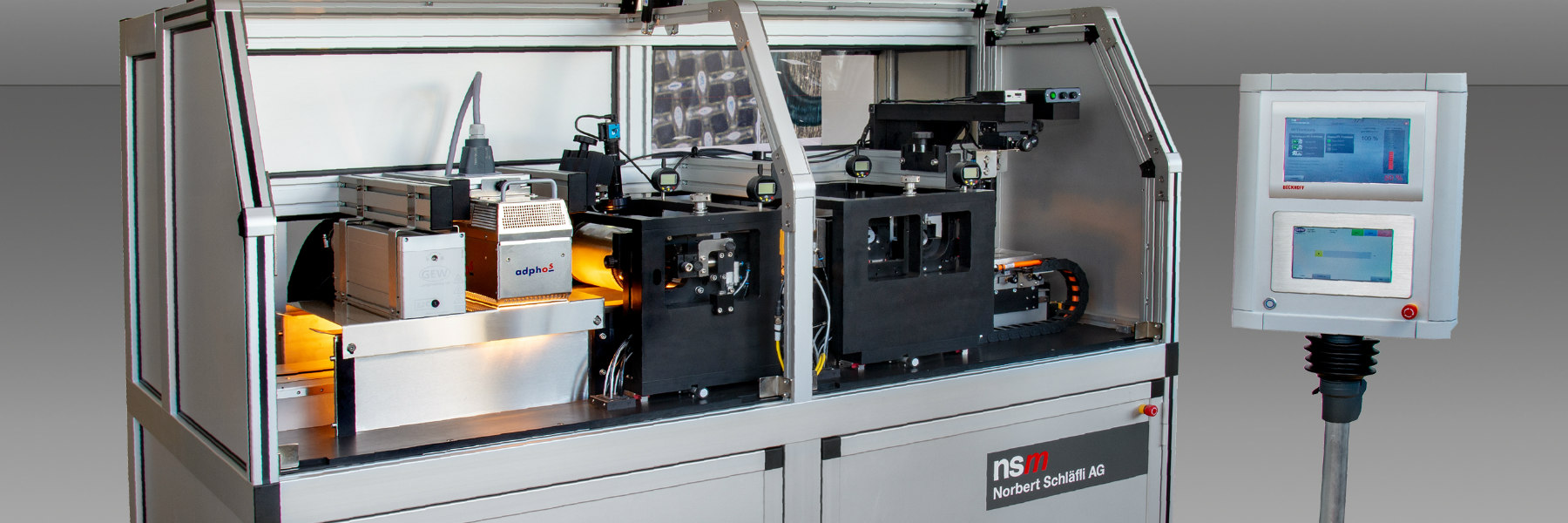

challenger 174

High-precision and multifunctional printing system

The challenger 174 is a high-precision and multifunctional printing, coating and laminating system. It is predestined for the development of printed electronics and printed functional devices. The challenger 174 offers tremendous possibilities with its multiple printing, laminating and inline drying stations. It offers highly accurate positioning accuracy, thus opens new dimensions for the development of printed elelctronics and printed functional devices.

For use in R&D, pilot and production application in a wide range of industries.

- Multiple printing, laminating and inline drying stations

- Printing, coating and laminating both flexible (foils) and rigid (glass and silicon) substrates

- Optical alignment system with integrated cameras

- Measuring software for real-time inspection

- Highly accurate positioning accuracy +/- 10 μm

- Small fluid volume per print <1 ml

Printing, coating and laminating units

- Gravure

- Gravure Offset

- Flexo

- Screen

- Slot die

- Inkjet

- Substrate handling and positioning system

- Laminator, etc.

Drying units

- UV

- IR (NIR)

- Photonic curing

Technical data and performance

- High-precision linear guides for precise movement of the substrate carriage (vacuum chuck)

- Easy to operate via colour touch screen

- Reliable and user-friendly BECKHOFF control technology

- Precise control of impression and doctor blade (pressure and angle)

- Cylinder size suitable for standard printing form manufacture available from multiple suppliers

- Printing size: 150 x 150 mm or larger sizes

- Process speed: Up to 30 m/min.

- Length: 1200 mm

- Width: 880 mm

- Height: 1615 mm

- Weight: 250 kg

Impressions challenger 174