nsm Norbert Schläfli AG is a full service provider

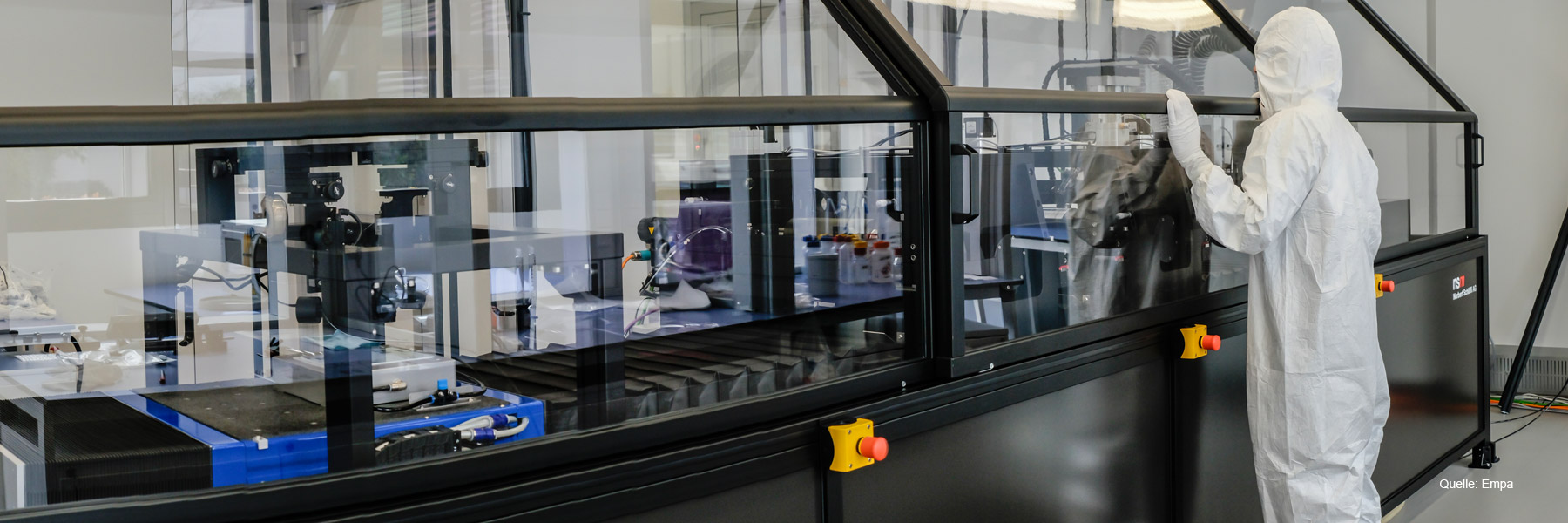

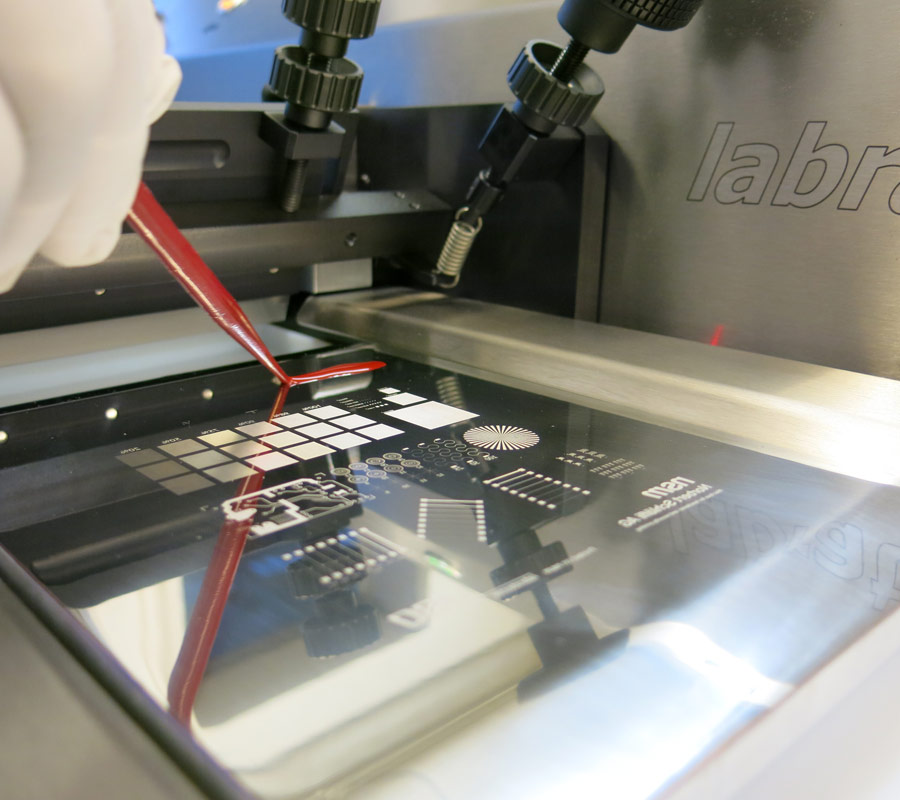

Test trials at nsm

Test your substrates and inks under production conditions on our laboratory printing/coating presses. For the print/coat tests, you can also use UV belt dryers, ovens and spectrophotometers. Thanks to a large stock of printing plates with various motifs and engraving parameters, a first test often produces meaningful results. We are specialized in producing customized print forms from your data.

Rental equipment

We make it possible for you to do a simple pilot test without high investment costs at your site. After professional training by our printing specialists, you can carry out tests indenpendently.

Consulting and supporting

- Research and development of processes

- Constructing and manufacturing of optimized, customer specific printing equipment

After sales service

Training of your employees

Laboratory supervisors, operating and maintenance staff are trained on-site and on your own line. Training content is tailored to your line and your needs.

Maintenance contract

The nsm maintenance contract ensures – besides rapid, professional assistance – comprehensive service and advice.

Remote maintenance

If requested nsm can access your machine, allowing quick and easy remote problem-solving. Remote access allows us to switch off faults as well as to optimize parameters so that your production can be resumed as quickly as possible.

Assembly and commissioning

nsm’s team of highly qualified technicians, engineers and process technicians is ready to help you with the assembly and commissioning of your line. After finishing the installation, dry and wet commissioning and the acceptance test runs are carried out under supervision by nsm.

We also offer tailor-made solutions and adjustments to your products. As additional service, we train your staff before, during and after the commissioning phase.